Services

Reactor Skimming

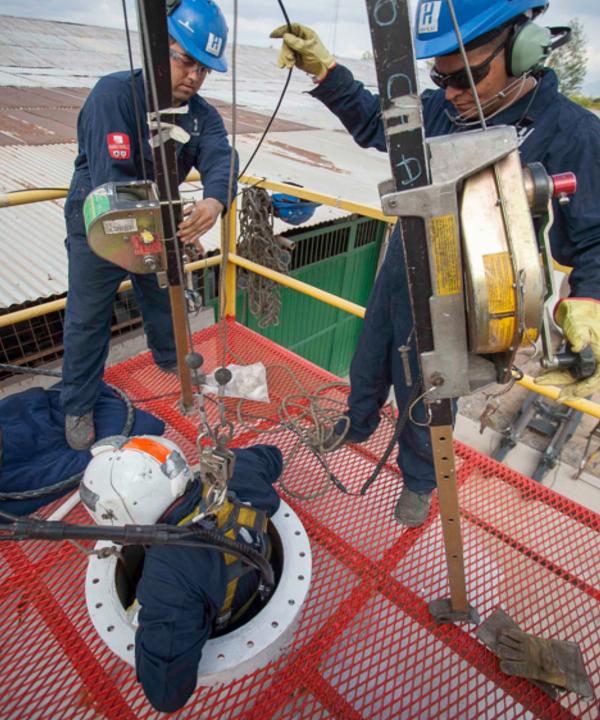

Service: Reactor skimming.

During the operation of the reactors, undesirable cracking reactions occur, the reaction products of which are deposited on the surface of the catalytic bed. Additionally, when processing products from delayed coking or catalytic cracking units, it is possible that a layer of fine particles is deposited that covers the empty interstices that form between the catalyst particles. This plugging makes it difficult for the reaction products to flow through the reactor. This implies an increase in the pressure drop and consequently a decrease in the performance of the reactor.

HANDCAT offers its customers the Reactor SKIMMING service. This work, carried out in an inert atmosphere, consists of removing the upper layer of the catalyst bed where the volume of pollutants that cause the high pressure drop and its exchange for fresh catalyst is concentrated. This allows to substantially extend the operating cycle of the equipment. The fundamental advantage of SKIMMING is to have the reactor back in service with a minimum loss of time and production.